There is a correlation between the diameter of the male hook and the female receiver. If the receiver is too small, it will not allow the connection. If it is too large, the hook will be able to be lifted out. The male hook should be a 5/8 inch steel rod with an angled 30-degree tip that is welded to frame at both ends – Female receptor must be 3/16 by 1.5-inch steel plate welded to frame on both outer sides. In the current market, many barriers are produced without true interlocking capability. There is the misconception that if barricades can simply hook together, that is usually “good enough.” This overlooks serious and potentially dangerous scenarios when barricades must interlock to maintain safety and order. How can you tell if a barrier is truly interlocking? You must ask about the hook.

Request a Quote for Classic Steel Barricades

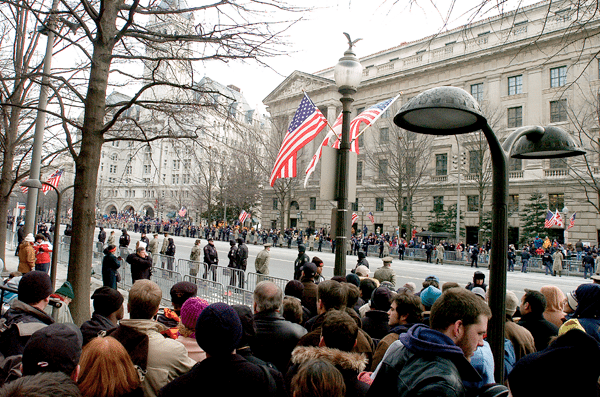

A crowd could easily destroy the integrity of a line of barricades by lifting them up – one person, or a group of people, only needed the strength to lift about 50 pounds.

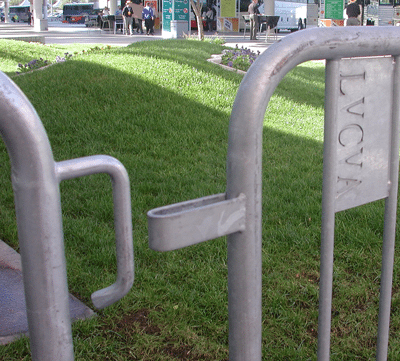

The objective was to make two crowd control barriers connect in such a way that, in a line, no single barrier could be removed from the line.

Samia accomplished this with a bend in the top male hook, which would enter a female receiver at an angle of about 30 degrees. Thus, when the frame was straightened, the “tip bend” would not have space to be pulled out.

There is a correlation between the diameter of the male hook and the female receiver. If the receiver is too small, it will not allow the connection. If it is too large, the hook will be able to be lifted out.

The male hook should be a 5/8 inch steel rod with an angled 30-degree tip that is welded to frame at both ends – Female receptor must be 3/16 by 1.5-inch steel plate welded to frame on both outer sides.

In the current market, many barriers are produced without true interlocking capability. There is the misconception that if barricades can simply hook together, that is usually “good enough.” This overlooks serious and potentially dangerous scenarios when barricades must interlock to maintain safety and order.

How can you tell if a barrier is truly interlocking? You must ask about the hook.

Blockader.com is a division of Tamis Corporation.