Advantages of Blockader Interlocking Barriers: Elevating Safety and Quality Standards

Both classic and standard steel barriers: Our philosophy is, quality first.

Explore the Unrivaled Benefits of Classic and Standard Interlocking Steel Barriers

At Tamis© Corporation, we hold steadfast to the principle of ‘quality first.’ Our range of Blockader Interlocking Barriers exemplifies this philosophy by offering both classic and standard steel barriers that not only meet but surpass industry safety and quality standards. Discover the exceptional advantages that set our interlocking barriers apart, ensuring your crowd control and security needs are met with the utmost excellence.

Blockader Interlocking Barriers represent a class of crowd control and security solutions renowned for their unparalleled performance and robust construction. As a pioneering force in the industry, Tamis© Corporation has consistently pushed the boundaries of safety and quality, and these barriers are no exception. Their enduring design and unwavering reliability are designed to exceed your expectations.

Our classic steel barriers stand as a testament to the enduring value of timeless design. Crafted with precision and attention to detail, they offer an enduring solution for crowd management and event security. Whether you’re safeguarding construction sites, managing large crowds at events, or directing traffic with precision, these classic steel barriers deliver on every front.

In parallel, our standard steel barriers uphold our commitment to quality and safety. Designed to meet the rigorous demands of today’s events and security needs, they provide a versatile and dependable solution for a wide range of applications. From public gatherings to traffic control, their resilience and performance ensure that your crowd control needs are met efficiently.

With Tamis© Corporation, you can trust that our Blockader Interlocking Barriers are more than just physical barriers; they embody our unwavering dedication to delivering top-tier crowd control solutions that set the standard for safety and quality. Elevate your event or site security with barriers that offer longevity, reliability, and peace of mind.

16 gauge steel in both the frames and the bases.

Stronger Steel prevents deterioration and distortion, without adding excess weight to the barrier.

Bolt-on replaceable bases.

Enables easy replacement – simply replace the base of the barrier and not the entire barrier itself.

Male hooks inserted into and welded to the frame at both ends.

Results in hooks which last much longer than single-welded hooks.

Vertical bars (uprights) inserted into frames before welding.

Inserting before welding is a superior technique to spot welding (which results in easier breakage).

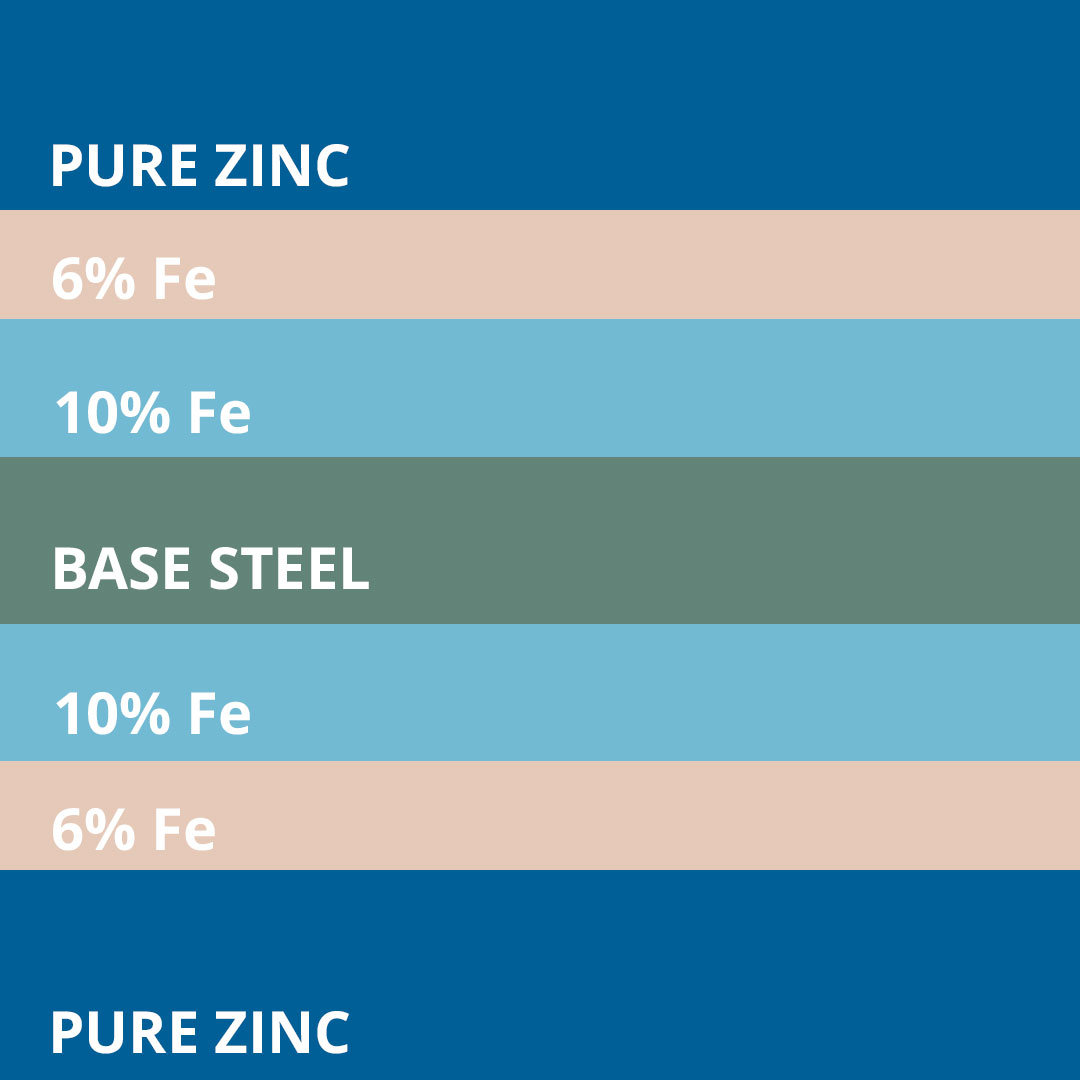

Hot-dip galvanizing.

The best protection for steel, resulting in a longer life span for your barriers. Barriers that are merely painted will rust.

Saddle-Cut Welds.

Much stronger than simple spot welding, saddle-cut welding results in superior strength and durability.

Cover your new barriers with jackets to display branding, messaging or advertising. Head over to our Barrier Jacket division’s website for more information.